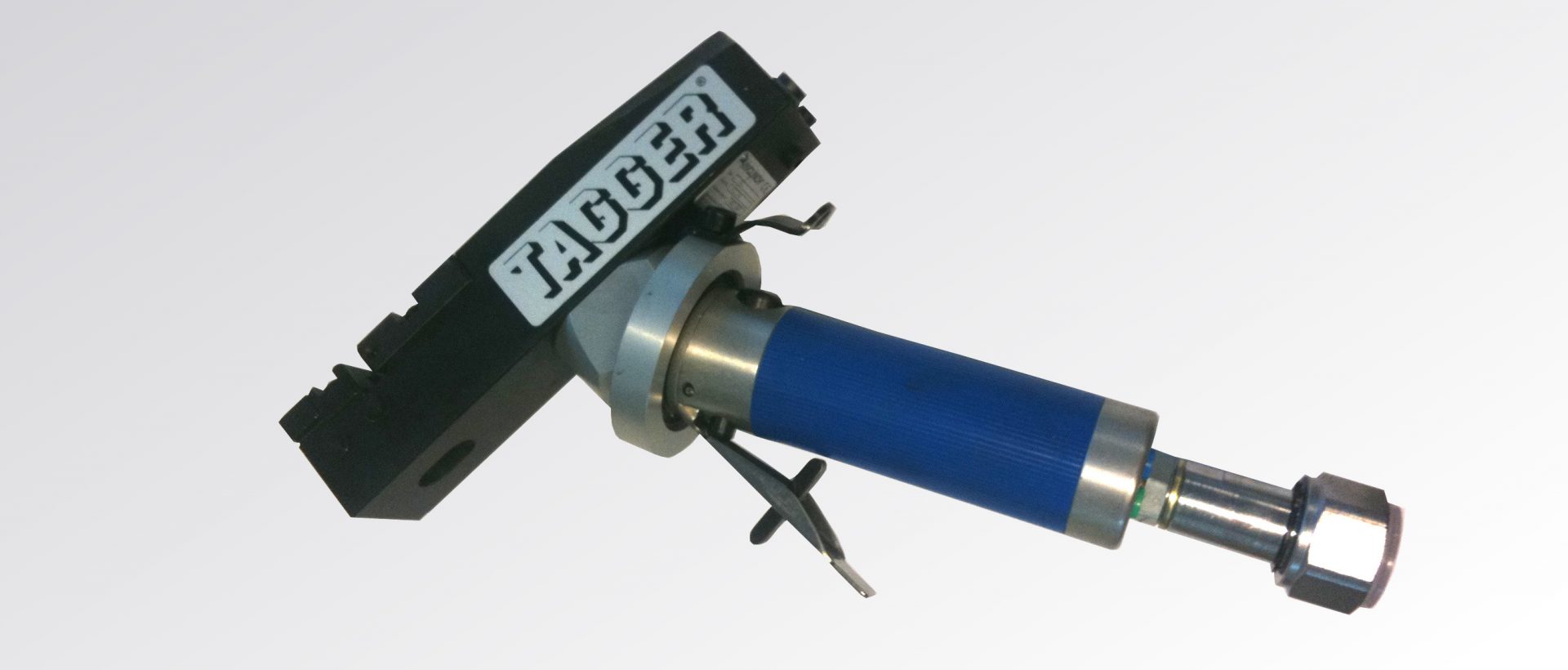

RIVSET® Portable

Devices and systems for joining sheets and profiles without fasteners.The clinching process is a method of joining sheet metal or

Devices and systems for joining sheets and profiles without fasteners.

The clinching process is a method of joining sheet metal or extrusions by localized cold-forming the materials.

The result is an interlocking friction joint between two or more layers of material formed by a punch into a special die.

Coated and painted sheet metals can also be joined together with no damage to the surface finish.

The RIVCLINCH® joining technique can be used to join steel and stainless steel materials as well as aluminum and/or non-ferrous materials in a cost effective, environmentally friendly process.

The product range of RIVCLINCH® systems are designed for different application ranges and adapt to varied manufacturing environments.

Benefits:

Steel- and stainless steel materials and also aluminum and other nonferrous metals can be joined econonical and enviromentally friendly.

In the RIVCLINCH® joining process the materials to be joined are first forced into the die by the punch. As soon as the bottom-most material is sitting on the die anvil it starts to flow laterally under the pressure being exerted by the punch. This causes the movable die sections to be pushed outwards and allows the flowing of the material to form the button. The punch then travels back to its starting position either by the operator or a pneumatic timer removing the force. The joined part can now be removed and the side sections of the die are drawn back together by a spring.

This local deformation of the material forms an interlocking friction joint.

The RIVCLINCH® joining system can be incorporated into existing press systems or custom built machines.

It can be used to set one or several points at the same time and can be integrated within manual machines and into robotic equipment and systems.