FAST TURN

Efficiency Quick opening and closing Quick subassembly installation without tools Counterclockwise and clockwise opening Easy closing by turning or axial

Efficiency

Reliable

Insulation

Many designs

We also realise customer-specific design requests regarding geometry and colour of the locking bolt head, so that you get just the right fastener for your installation space.

QUICKLOC® Quick releases – Designs:

QUICKLOC® standard design

Different designs of QUICKLOC® locking bolts and lock bottoms are always on stock or can be produced with short lead times. Please see pages 10 to 12 for the design range. Apart from those designs, QUICKMatch can be used to configure more than 2,000 different variants. Please do not hesitate to ask.

QUICKLOC® special design

Feel free to contact us for customised quick releases.

QUICKLOC® Quick releases – Function:

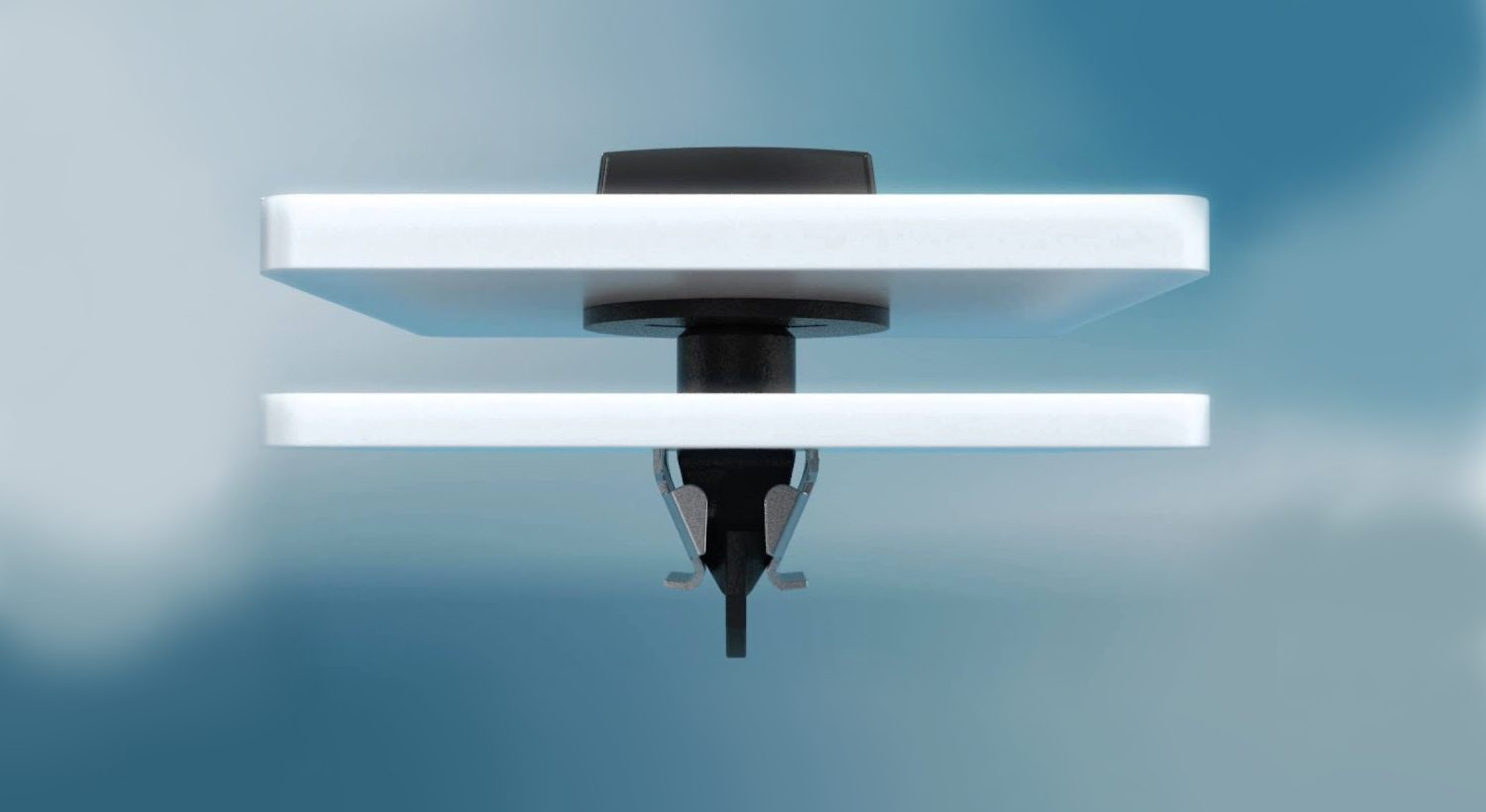

1. Clipping the receptacle into a square or rectangular hole.

2. Clip-fastened receptacle.

3. Insertion of locking bolt into bore hole; optional locking with retaining washer.

4. To lock the joint, the locking bolt is screwed into the receptacle under light pressure and locks in due to the fittingly shaped curve geometry. Thanks to its geometry, it is then held in place without clearance

5. When the joint is opened by a clockwise or counterclockwise quarter turn, the elastic part of the receptacle is stretched and the locking bolt released.